AI and Energy Efficiency: Suncor's Canadian Operations

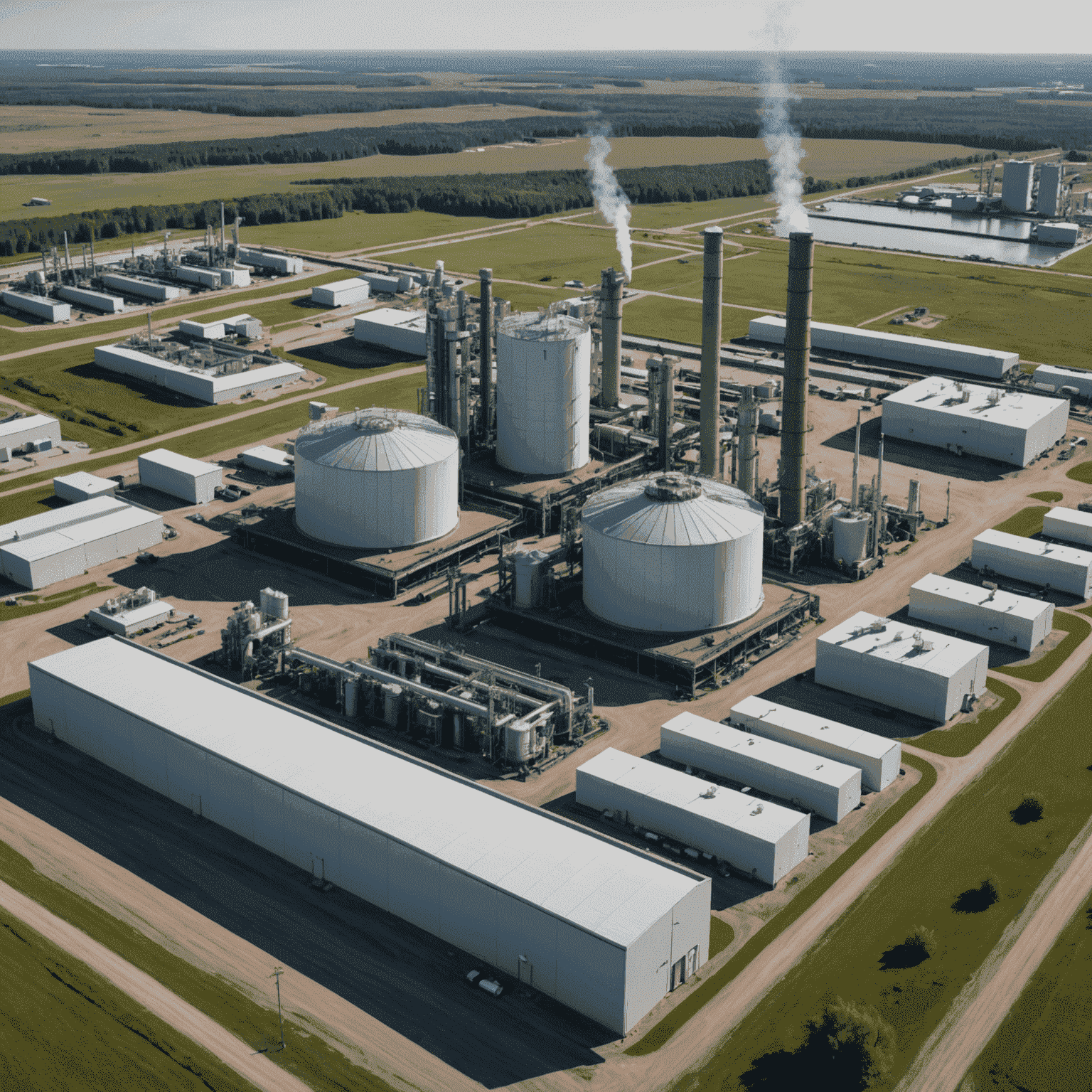

Suncor Energy, a pioneer in Canada's energy sector, is harnessing the power of Artificial Intelligence (AI) to revolutionize energy efficiency in its operations. This innovative approach not only reduces environmental impact but also optimizes production processes, setting a new standard for the industry.

AI-Driven Optimization

Suncor's implementation of AI technologies focuses on several key areas:

- Predictive maintenance to reduce downtime and energy waste

- Real-time monitoring and adjustment of energy consumption

- Optimization of extraction and refining processes

- Smart grid management for efficient energy distribution

Impact on Energy Efficiency

The integration of AI has led to significant improvements in Suncor's energy efficiency:

Key Achievements

- 15% reduction in overall energy consumption

- 20% increase in production efficiency

- 30% decrease in maintenance-related downtime

- 10% reduction in greenhouse gas emissions

Future Prospects

Suncor continues to invest in AI research and development, aiming to further enhance energy efficiency across its Canadian operations. The company is exploring advanced machine learning algorithms, edge computing, and IoT integration to push the boundaries of what's possible in energy-efficient oil and gas production.

As Suncor Energy leads the way in AI-driven energy efficiency, it sets a powerful example for the entire industry. By leveraging cutting-edge technology to reduce environmental impact and improve operational efficiency, Suncor is not just adapting to the future of energy production – it's actively shaping it.