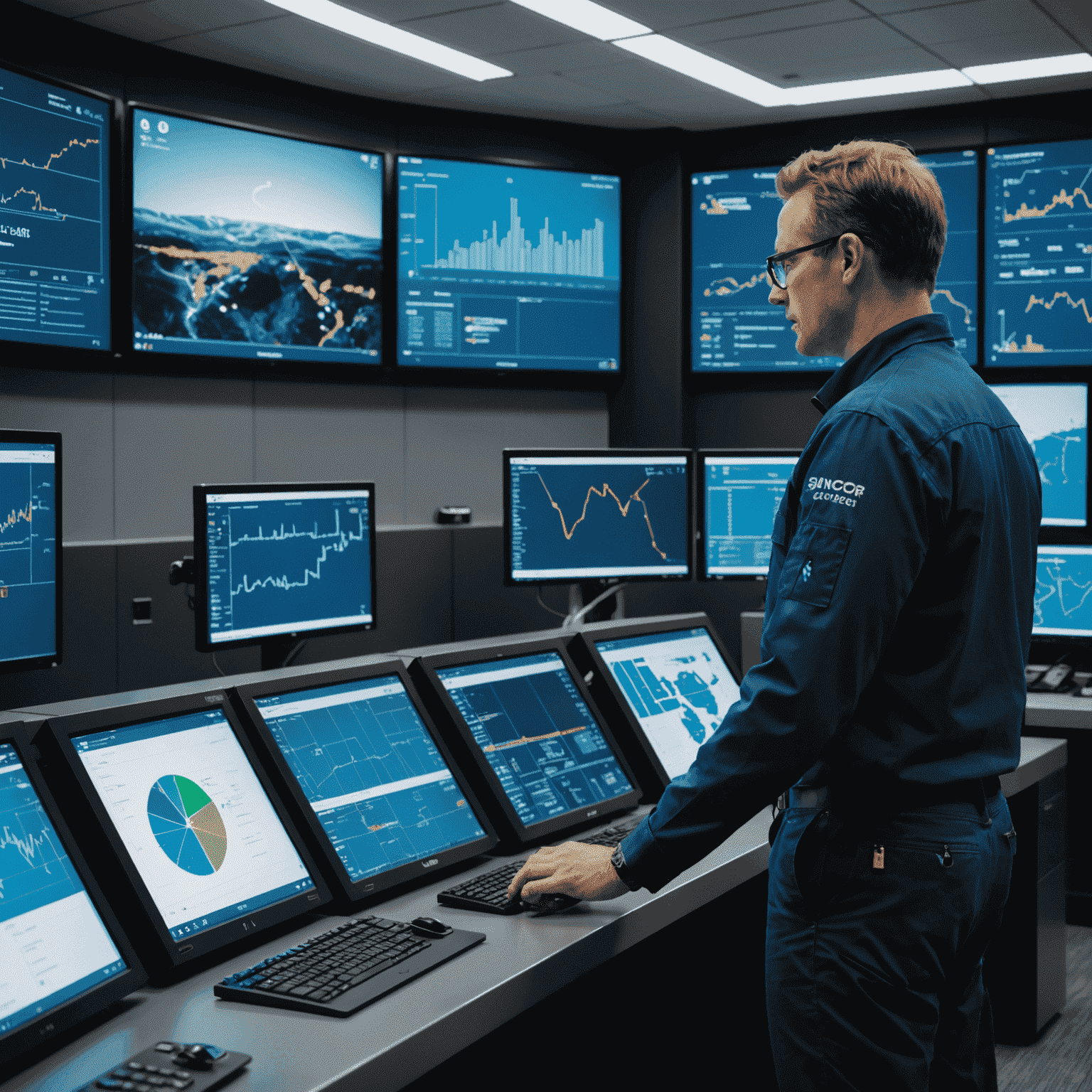

Predictive Maintenance using AI: Suncor's Innovative Approach

Suncor Energy, a pioneer in Canada's energy sector, is leveraging the power of Artificial Intelligence (AI) to revolutionize its maintenance practices across its Canadian sites. This innovative approach is setting new standards in predictive maintenance, significantly reducing equipment failures and optimizing operational efficiency.

The AI Revolution in Maintenance

Suncor's implementation of AI in predictive maintenance is a game-changer for the energy industry. By analyzing vast amounts of data from sensors and equipment logs, AI algorithms can predict potential failures before they occur, allowing for proactive maintenance and minimizing costly downtime.

Key Benefits of AI-Driven Predictive Maintenance

- Reduced unplanned downtime

- Increased equipment lifespan

- Optimized maintenance schedules

- Enhanced safety through early detection of potential hazards

- Significant cost savings in repairs and replacements

Suncor's AI Implementation Strategy

Suncor's approach to implementing AI for predictive maintenance involves several key steps:

- Data collection from various sources across Canadian sites

- Development of machine learning models tailored to specific equipment types

- Integration of AI predictions with existing maintenance systems

- Continuous model refinement based on new data and outcomes

- Training of maintenance teams to work alongside AI systems

Real-World Impact

The implementation of AI-driven predictive maintenance at Suncor's Canadian sites has yielded impressive results:

- 30% reduction in unplanned downtime

- 20% increase in equipment lifespan

- 15% reduction in maintenance costs

- 50% improvement in early detection of potential failures

Future Outlook

As Suncor continues to refine and expand its AI-powered predictive maintenance program, the company is setting a new standard for the energy industry in Canada and beyond. This innovative approach not only enhances operational efficiency but also contributes to safer, more sustainable energy production.

The success of Suncor's AI implementation in predictive maintenance serves as a compelling case study for how Artificial Intelligence can transform traditional industries, paving the way for a more efficient and technologically advanced future in energy production.